Case Studies

- Home

- Case Studies

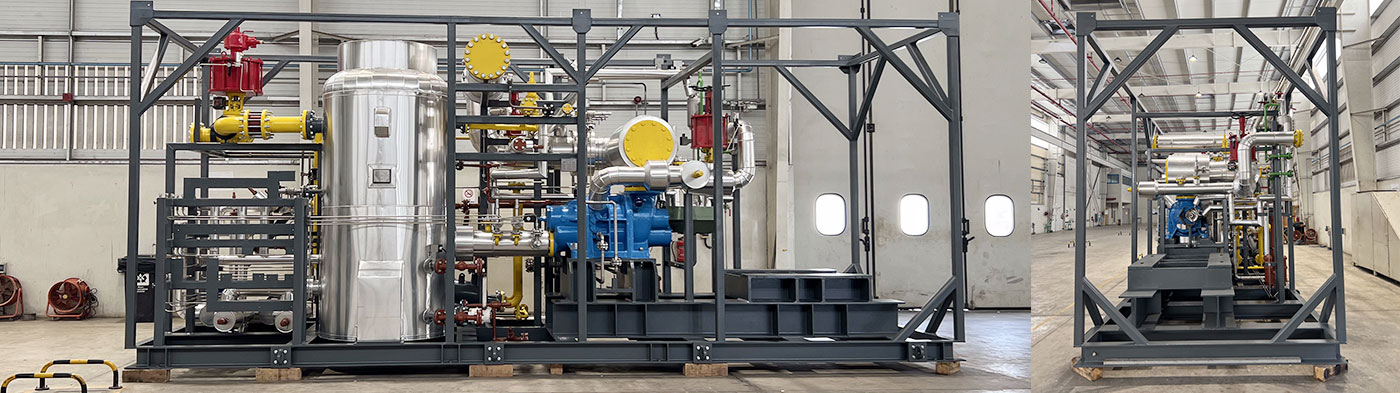

- Packaged Skid System for Refinery Process Optimization

Packaged Skid System for Refinery Process Optimization

Delivering Customized, High-Performance Skid Solutions for Seamless Refinery Operations

ADEAREST successfully supplied a packaged skid system for a refinery project, engineered to meet the critical process requirements of the facility. The fully integrated skid was designed as a compact and efficient solution, incorporating advanced equipment to handle complex fluid handling and processing tasks within the refinery's operations. The packaged skid allowed for easy installation and seamless integration into the refinery’s existing systems, offering operational flexibility and efficiency.

At the heart of this project was the GEA screw compressor, chosen for its exceptional reliability and performance in industrial applications. The screw compressor was used for process compression tasks, ensuring smooth and efficient operation under the rigorous conditions typical of refinery environments. The skid system also featured advanced automation, comprising of a PLC control system to monitor and manage the process in real time. This ensured precise control over key parameters and operational safety.

The skid’s modular design facilitated quick installation, reducing the need for extensive site work. Additionally, the system included ASME-certified pressure vessels and piping, designed to handle high-pressure operations in compliance with the refinery’s stringent safety standards. The robust construction and reliable components ensured that the system could operate continuously with minimal maintenance, improving the overall productivity and efficiency of the refinery.